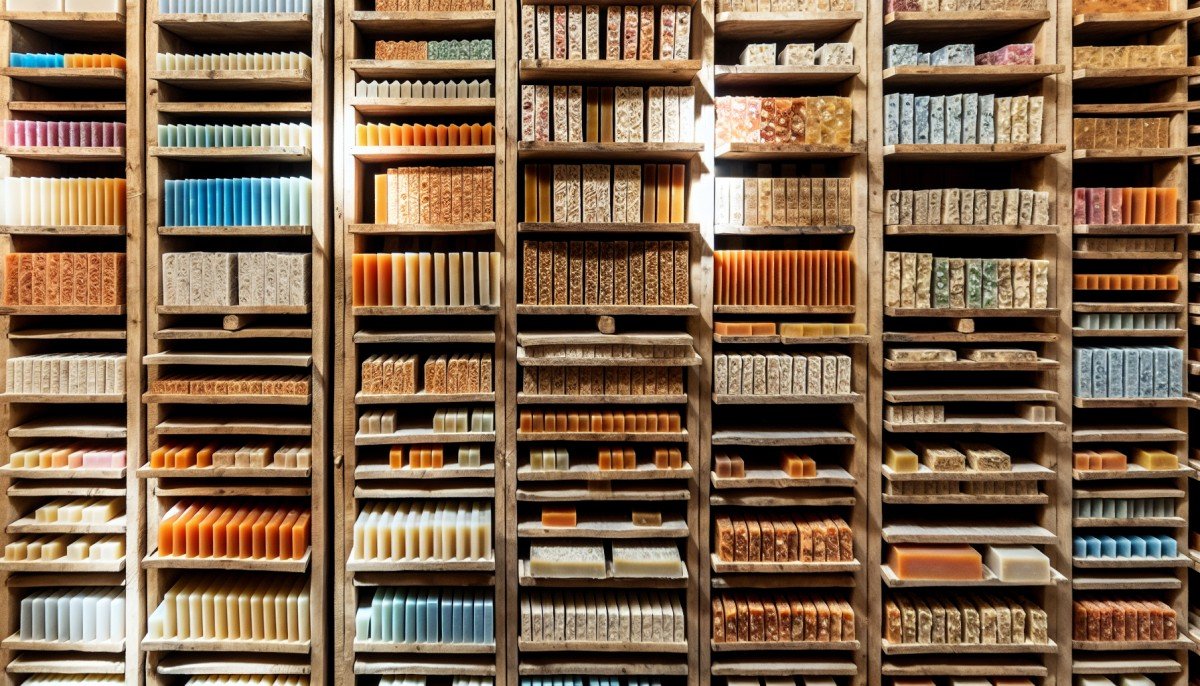

If you’ve ever made soap, you know that the curing process is essential for creating the perfect bar. This crucial step allows the soap to harden, reach its optimal pH level, and develop its full scent profile, ensuring it’s safe and effective for use. While curing might sound straightforward, the environment in which you cure your soap can make all the difference. This is where soap curing racks and shelving come in. In this ultimate guide, we’ll dive into why soap curing racks and shelving are crucial for the soap-making process, how to choose the right ones, and how they can impact the quality and efficiency of your soap production.

Why Curing Matters in Soap Making

Before we explore the role of racks and shelving, let’s quickly review the curing process and why it’s so important. Soap is made by combining fats (like oils or butters) with an alkali (typically sodium hydroxide, or lye) in a process called saponification. The soap is then poured into molds and left to solidify.

However, even after the soap has hardened, it isn’t ready for use. It needs time to fully cure, which involves:

1. Water Evaporation: During curing, the soap loses excess water. This is essential because it helps the soap harden and become milder, which improves its lather and longevity.

2. pH Adjustment: Fresh soap typically has a high pH due to the lye content. Curing allows the pH to balance out, making it gentler on the skin.

3. Scent Development: As the soap cures, the scent may evolve, and the harshness of certain fragrances can dissipate, leaving behind a smoother, richer aroma. Without proper curing, your soap may remain too soft, overly harsh, or prone to breaking down quickly in water. This is where the right curing environment becomes crucial.

4-Tier Foldable Curing Rack for Soaps

Perfect for drying your handmade soaps evenly and efficiently while saving space in your kitchen

Product information

$40.99 $38.99

Product links

The Role of Soap Curing Racks and Shelving

Curing racks and shelving are designed to provide the optimal conditions for soap to cure effectively. While it’s possible to improvise, using dedicated racks or shelves offers several advantages:

1. Airflow. Soap needs consistent airflow on all sides during the curing process to allow moisture to escape. Curing racks are typically designed with open spaces between each soap bar, ensuring the soap dries evenly. Shelving systems that don’t allow proper air circulation can lead to soap becoming too soft or drying unevenly, resulting in bars that may have a poor texture, weak lather, or a shortened shelf life.

2. Organization. For soap makers, efficiency is key, especially if you're creating large batches. Curing racks and shelving systems help you organize your soaps by batches, scents, or types. This makes it easier to track curing times and manage different stages of production.

3. Space Optimization. Soap curing can take anywhere from 4-6 weeks, depending on the recipe. If you’re making soap regularly, this can take up a significant amount of space. A well-organized rack or shelving system helps you maximize your area for curing your soap, even in small spaces. Stackable shelves or multi-tiered curing racks allow you to increase your output without taking over your entire workspace.

4. Protection . Curing racks and shelves help to keep your soaps off the ground, reducing the risk of contamination from dust, dirt, or pet hair. Additionally, having your soaps elevated on racks helps maintain cleanliness and prevents accidental damage (such as soap bars sticking together or being squashed).

5. Prevents Uneven Curing. Stacking soaps on top of one another or curing them in tight, closed spaces can hinder airflow, leading to uneven curing. Curing racks that provide ample space between bars allow each one to dry evenly and maintain its integrity, ensuring a consistent final product.

How to Choose the Right Soap Curing Rack or Shelving

Choosing the right soap curing racks and shelving involves considering factors such as airflow, space, material, and durability. Here’s a breakdown of the key features to look for when selecting the ideal curing setup:

1. Material

- Wood: Many soap makers prefer wooden racks because wood is naturally breathable, which helps facilitate air circulation. Be sure to choose a non-toxic wood (such as untreated pine or cedar) that won’t leach chemicals into your soap. Wood also has the benefit of being naturally antimicrobial, reducing the chance of mold or bacteria growth.

- Metal: Metal racks, especially stainless steel, are sturdy, easy to clean, and resistant to corrosion. They can handle heavier soap batches and tend to last longer in humid environments. However, metal racks may not offer as much natural breathability as wood.

- Plastic: While lightweight and easy to maintain, plastic racks may not provide the same level of air circulation as wood or metal. If you go with plastic, ensure that the material is durable, non-toxic, and BPA-free.

5-Tier Bamboo Soap Drying Rack

Keep your handmade soaps organized and beautifully displayed while allowing them to dry effortlessly

Product information

$59.99

Product links

2. Size and Capacity

- Number of Bars: Depending on the volume of soap you produce, you’ll need racks that can accommodate several bars at once. For small-batch soap makers, compact racks may suffice, but larger operations might require multi-tiered shelves or expansive wall-mounted racks to handle high production volumes.

- Adjustable Shelves: Look for racks or shelving that have adjustable shelves to accommodate different soap bar sizes and allow flexibility as your production needs change.

3. Ventilation : Ensure that the design of the racks or shelves allows proper airflow. Open slats, grids, or wire shelving can provide the necessary ventilation to help soaps cure evenly. Avoid shelves that have solid, non-permeable surfaces that could trap moisture and slow down the curing process.

4. Ease of Cleaning:

Curing soap involves moisture, and that moisture can accumulate over time, potentially leading to mold or residue buildup. Choose racks or shelving that are easy to clean and maintain. Racks with removable trays or easily washable surfaces will save you time and prevent contamination.

5. Space-Saving Features:

If you’re working in a small space or a home-based workshop, consider curing racks or shelving systems that can be stacked, wall-mounted, or folded away when not in use. Adjustable or modular shelving allows for flexibility in how much space you need and how it’s organized.

DIY Soap Curing Racks vs. Commercial Options

If you're on a budget or want to customize your setup, you can build your own soap curing racks. Simple DIY options might include:

- Wooden Planks: Create a simple rack using slats of untreated wood spaced apart to allow air circulation.

- Wire Mesh: Using a metal grid or chicken wire, you can build a curing rack with ample airflow. However, for larger operations or those who want professional-grade equipment, commercial soap curing racks may be a better investment. These often come with pre-designed features such as adjustable tiers, heavy-duty materials, and the ability to hold large quantities of soap.

Tips for Maintaining the Best Curing Environment

- Humidity Control: Soap should cure in a dry, well-ventilated area. Too much humidity can slow down the curing process, leading to soggy or uneven soap. Use a dehumidifier if necessary.

- Temperature: Ideal curing temperatures range between 60°F and 80°F (15°C to 27°C). Avoid places that are too hot or too cold, as extreme temperatures can impact the curing process.

- Rotate Your Soap: Occasionally rotate your soap bars on the racks to ensure even curing on all sides. This helps prevent soft spots and ensures a consistent texture.

Conclusion

Soap curing racks and shelving are more than just a convenience—they are an essential part of the soap-making process. They ensure your soap cures evenly, protects your bars from contamination, and maximizes the efficiency of your production. Whether you’re a hobbyist creating a few batches at home or a larger operation producing soap for sale, investing in the right curing equipment can improve the quality and consistency of your products. By considering the material, airflow, and capacity of your racks or shelves, you can create an ideal environment for your soap to cure, leading to better, longer-lasting bars that your customers will love. Whether you opt for DIY or commercial options, having a proper soap curing system will elevate your soap-making process and ultimately your business.